For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Downflow Booths

- Home

- Downflow Booths

- Downflow Booths

As the UK’s leading downflow booth manufacturer, our dust extraction downflow booths are specifically designed to offer the containment of dust and contaminants over large areas of emission, where conventional hoods are neither adequate nor effective. Our downflow booths are available in an array of sizes, all of which offer suppression and extraction of dust over the entire area.

Select from the products below, or for more advice on these or other products within our range please contact our team on 01664 410 641 and they will be happy to assist you.

Why Choose a Downflow Booth?

With the potential for serious harm to workers who are subject to an occupational dusty environment, downflow booths are essential in providing protection during the handling of hazardous materials. Designed to offer control over these environments, our downflow booth dust extraction systems also reduce the risk of combustion by extracting the contaminates from the entire working area.

As Seen On The BBC

Our downflow booths are perfect for food processing and food production.

Specifically designed to offer the containment of dust and contaminants over large areas of emission, our extraction booths offer fantastic food safety and hygiene for the food industry

Download Our Brochure

STAINLESS STEEL WALK-IN UNITS

TO SUIT THE NEEDS OF YOUR BUSINESS

Our downflow booths have been designed and engineered to be of modular construction and they are manufactured in stainless steel.

As standard, our booths begin at 2 metres and are available in widths up to 8 metres. Customised widths can be manufactured to meet your specific requirements.

The day-to-day use of the booth is simple, demanding no technical knowledge for its use.

The control panel is designed with integral pressure indicating devices to monitor the performance of the extraction, together with automatic control of the variable speed fans to maintain optimum operating conditions.

The start/stop buttons are supported with indicator lights that show that the booth is running correctly. As standard, the booth comes with one twin IP66 socket.

The Federation of Bakers, Launches Revised Dust Guidance 'Blue Book'

Guidance on dust control and health surveillance in Bakeries

After 22 years, the UK's Federation of Bakers (FoB) has released its revised industry dust guidance. So what does this mean? Adhering to the guidance will help businesses meet their duty of care for employees; helping to ensure that the highest health and safety compliance is implemented throughout the everyday processes of baking.

- The new guidance provides essential information and advice for large bakers and the food manufacturing industry to help them minimise risk to their employees, reducing the exposure of flour and other airborne dust contaminates.

- Specifically, it provides advice on how to help assess the specific dust levels within the work environment of the bakery and highlights a range of practical measures that can be implemented in order to reduce the overall exposure to this.

To find out more about how Flextraction can help provide essential dust containment for your industrial food processes, get in touch today. Telephone - 01664 410 641 or Email - sales@flextraction.co.uk

To download the full guidelines, click the link below

Our Downflow Booth In Operation

The day-to-day use of the booths is simple, demanding no technical knowledge.

The control panel is designed with integral pressure indicating devices to monitor the performance of the extraction, together with automatic control of the variable speed fans to maintain optimum operating conditions.

The start/stop buttons are supported with indicator lights that show that the booth is running correctly.

Downflow Booth Features

Stainless Steel Walk-in Booth Dust Extraction Units

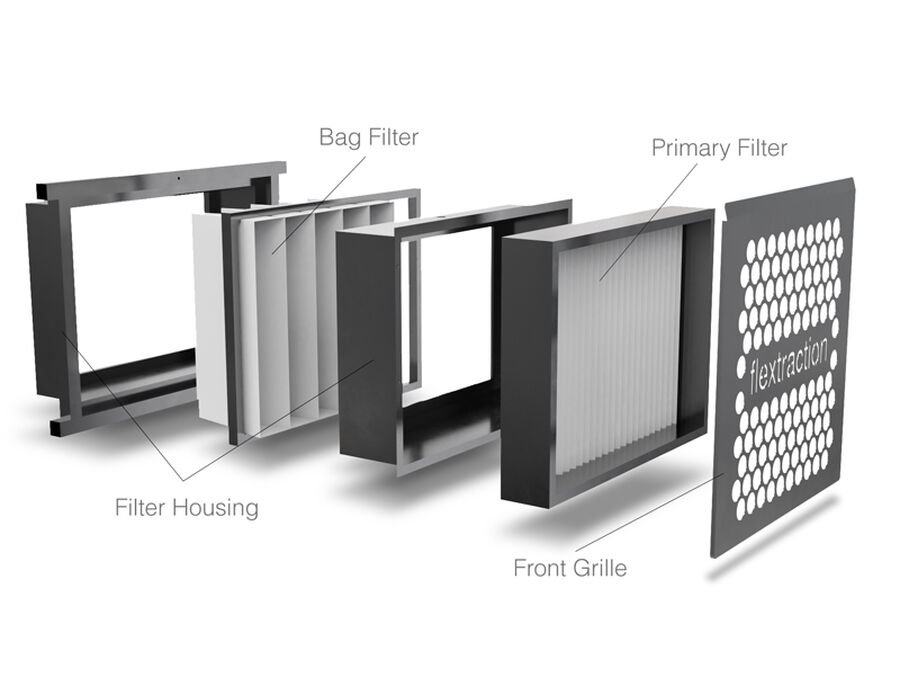

The Downflow Booth offers suppression and extraction of dust over the whole area, as shown. For such powder handling applications, the Flextraction Down Flow Booth operates on a re-circulatory airflow principle. A clean downflow of air is supplied from the ceiling HEPA (High-Efficiency Particle Arrestor) filters suppressing any dust away from the operator's breathing zone. Louvred grilles in the lower rear wall capture the airborne contaminants and filter the air via three-stage filtration. This comprises of primary roughing filters, secondary bag filters and finally, HEPA filters discharging over the operator's head, providing a nominal evenly distributed downflow.

Fresh Air By Design

Filter Breakdown and Additional Details

Product Features:

- Designed to offer containment of dust over a large area.

- Suppresses dust below the operator's breathing zone into the extract area.

- Operates on a re-circulatory airflow principle.

- Has three-stage filtration: Primary roughing filters, Secondary bag filters, and High-Efficiency Particle Arrestor Filters.

For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Be first to hear of our special offers!