For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Welding Industry

- Home

- Industries

- Welding Industry

Fresh Air By Design - At Flextraction, we manufacture and provide a range of welding air filtration systems and welding fume extraction filters, in order for your business to provide the safest working environment for your staff within the vicinity of a welding process. The extraction of welding fumes is essential to the health and well being of the welder, even if the operation is being carried out only for short periods.

Select from the products below, or for more advice on these or other products within our range please contact our team on 01664 410 641 and they will be happy to assist you.

Why is Welding Fume Extraction so important?

Welding fume is subject to COSHH regulations

The fume created by welding and hot cutting processes is a varying mixture of hazardous airborne gases and very fine particles. Exposure to such gases increases the risk of lung-related illnesses, some of which can be fatal eg. asthma, lung ulcers, pneumonia and even cancer.

The installation of a correctly designed welding air filtration system used in accordance with the operating instructions ensures that welding fumes are extracted direct at source, creating a safer environment for all workers and staff in your business.

At Flextraction, we offer efficient local exhaust ventilation (LEV) to help your business reach HSE standard HSG258 and protect your workplace with a range of welding extraction arms, units and benches.

HPD Welding Fume Extraction Arms

What are the benefits of an extraction arm for welding fume?

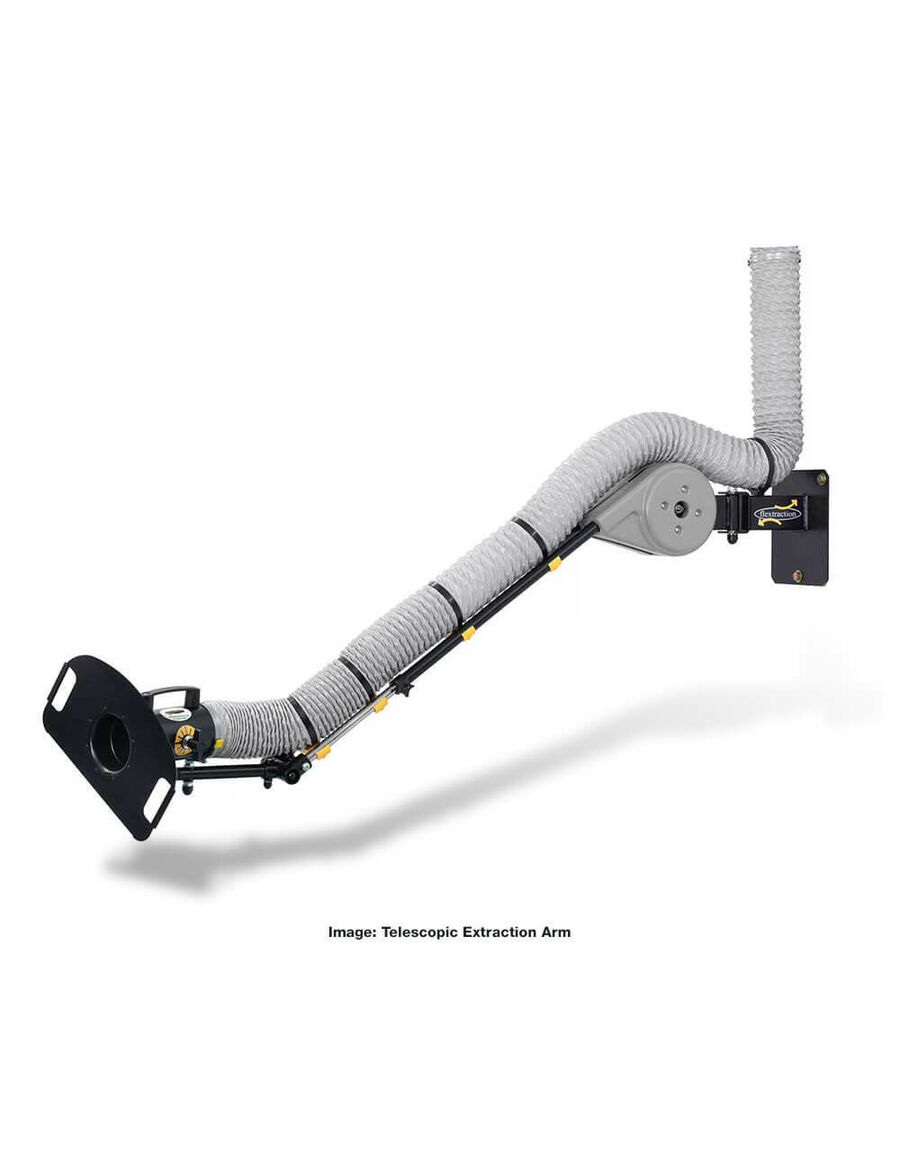

Flextraction have our own bespoke range of welding fume extraction arms (HPDs), with varying lengths, diameters and mounting options designed for the safe extraction of pollutants at source.

Our engineering expertise has developed the Hood Positioning Device, an elevated version of a standard extraction arm, with purpose-designed hoods able to be positioned wherever the welding process demands. Our arms have no internal components, avoiding wear, corrosion and airflow restrictions.

There are three main HPDs available:

- Articulated : available in 4 standard lengths, with extensions available up to 8m.

- Telescopic : length varying from 1.2m-1.65m depending upon its extended position.

- Mini : scaled down version of the articulated HPD, ideal for smaller working spaces - available in either 1m or 1.5m

Our HPDs are available in multiple diameters:

- 75mm, 100mm , 125mm diameter (available to mini arms)

- 160mm, 200mm diameter (available to articulated/telescopic arms only)

For more information on our welding arms,click here.

Made In The UK

Flextraction manufacture and supply all our own welding fume extraction arms

All of our extraction arms are supplied fully assembled, with a standard wall mounting bracket included.

Our arms are also available with:

- Ceiling or floor stanchion mounts

- Unit mounts / Up and down swivel

- Or as part of a centralised extraction system.

For a full scope of our wide range of brackets and hoods, click here.

On Torch Vacuum Unit - The XM Torch 20

Extract at source made easy with this on torch unit

The XM Torch by Depureco Industrial Vacuums offers extract of hazardous fume direct from the welding torch, used for applications such as long seam welding, welding in multiple positions and/or MIG welding.

The on torch vacuum is controlled directly by the welding machine, with a sensor positioned to detect when there is a flow of current.

Other features of the on torch are:

- one/two bypass motors reaching high airflows

- cellulose filter for welding fume

- jet clean filter cleaning system

- 1.3kW power

For more information on the XM Torch click here.

Mobile Welding Air Filtration System with Extraction Arm - The Cleango

Our #1 Mobile Welding Fume Extraction Unit

With flexibility in mind, the Cleango is our portable welding fume extraction unit of choice, offering filtration for an array of welding applications, including manual welding, MIG/AG/TIG welding and gas welding.

The Cleango has a variety of features, including:

- Compact mobile unit with castors

- Dynaflex extraction arm for direct extraction at source

- High efficiency filter cartridges

- Simple filter handling

- Electrical control panel

- Cellulose cartridge filter

For more information and full technical specifications, click here.

Mobile Downdraft Welding Fume & Dust Extraction Unit - The Smokart

Our top pick for a mobile downdraft extraction bench; complete with an integrated cleaning system for a pollutant free work environment.

Designed and manufactured by Coral Antipollution Systems, the Smokart is a mobile extraction bench designed to filter harmful particles derived from welding and grinding applications to protect the operator and the surrounding work area.

The Smokart is complete with various features including:

- Cartridge filter, activated carbon filter and H13

- Water sparks trap for grinding processes

- Compressed air cleaning system

- 1.1 - 2.2kW motor

For more information and full technical specifications, click here.

Welding Fume Extraction Downdraft Bench- The Poliweld

Offering an alternative option for extraction of welding fume and dust

For some welding processes, it may be that a downdraught extraction bench is an alternative, offering a multipurpose option suitable for additional applications such as grinding or sanding.

The Poliweld from Coral Antipollution Systems is our choice of downdraught bench for fume and dust from welding processes, with cartridge filters designed to capture fine dust and filter clean air back into the workplace environment.

For further information on the Poliweld click here

Mobile Grinding Filtration Unit - The Grindex

Specifically designed for all grinding extraction needs

Weld grinding is an important part of any metalworking process, and as such the correct extraction of grinding dust particles is crucial.

Flextraction can supply the Grindex DF, a mobile filtration unit complete with:

- Water sparks trap

- Self cleaning compressed air system

- Carbon filters for safely removing gases

- Inlet for additional extraction arm

- Direct connection to ductwork

For more details click here.

For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Be first to hear of our special offers!