For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Dust and Fume Extraction Arms

- Home

- Dust and Fume Extraction Arms

Extraction arms (also referred to as local exhaust ventilation) are positioned near the source of airborne contaminants and are equipped with an extraction hood that is placed directly at the point of dust and fume generation. As dust, mist, fumes, vapours, or harmful gases are produced, they are drawn into the hose and then transported to a safe emission point or external filter unit. At Flextraction, our range of extraction arms is the result of over 15 years of research, design and development and offers flexibility and effectiveness found nowhere else. By using high-quality, efficient dust and fume extraction arms, businesses can create a safer working environment for their employees. Whether you're looking for food-grade extraction arms, welding fume extraction arms, or laboratory extraction arms, contact the team at Flextraction and we'll be happy to advise on the right solution for your business.

Select the type of Dust and Fume Extraction Arms required, or for more general advice please contact our team on 01664 410 641 and they will be happy to assist you.

Articulated Dust & Fume Extraction Arms

At Flextraction, our dust and fume articulated extraction arms are purpose-built, and have been designed in-house for the removal of harmful contaminants at the point of source. They are specifically engineered to accommodate a range of hood and h...View the product range

Mini Dust and Fume Extraction Arms

Flextraction mini extraction arms are self supporting articulated extraction arm that have been designed and engineered for the removal of dust and fumes at source. They are customisable and suitable for smaller environments.View the product range

Telescopic Dust and Fume Extraction Arms

Flextraction's range of Telescopic Extraction Arms are self supporting and have been designed and engineered for the removal of dust and fumes at source. They offer additional reach benefits over our standard dust and fume extraction arms.View the product range

Extraction Hoods and Brackets

Whether it is an Articulated, Telescopic, Extended or Mini extraction arm we have a hood or bracket that will suit your specific requirements. When we do not have an off the shelf version we are able to design a hood to ensure your extraction arm ...View the product range

Welding Fume & Dust Extraction Arms

Welding is an essential process for many manufacturing and industrial metal fabrication applications. However, welding can produce harmful fumes and dust that can be dangerous to workers if inhaled. That's why welding fume extraction arms are an i...View the product range

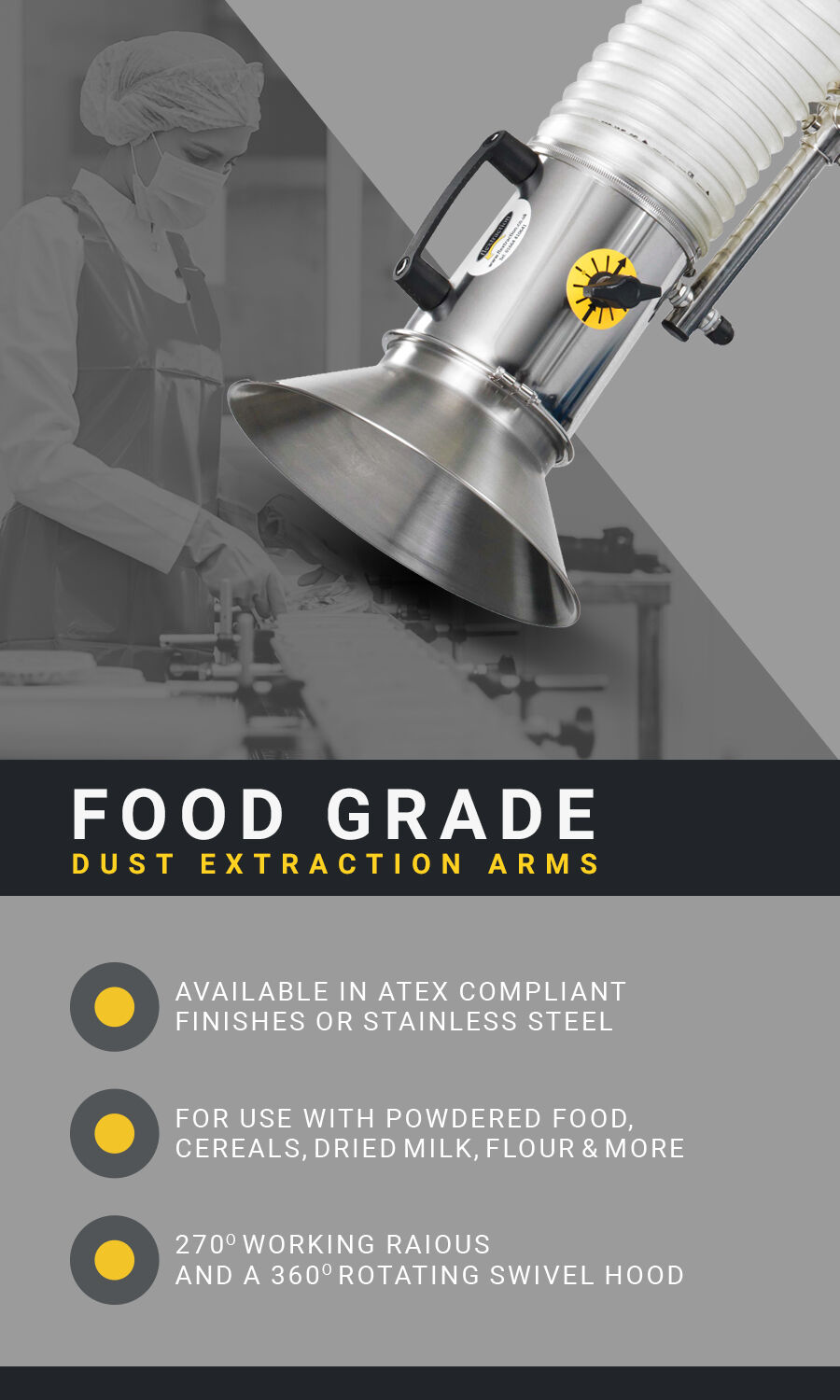

Food Grade Dust & Powder Extraction Arms

Our range of ATEX and stainless steel food extraction arms are designed specifically for food and drinks production. The safe removal of dust, and dried powders is essential when complying with hygiene requirements, especially in bakeries, on food...View the product range

Flexible Dust Extraction Arms

What is an extraction arm and how do they work?

Dust and fumes can be created during a variety of industrial processes, including fabrication, welding, grinding, sanding, and soldering. These particles can pose a serious threat to workers' health, as they can be inhaled and cause respiratory problems. In order to protect the health and safety of your workers, dust and fume extraction arms are an effective way to remove contaminants generated around a workshop or industrial working environment.

An extraction arm is essentially a hood connected to a hose that uses a negative draft to draw up dust particles, fumes, and vapours (away from a working environment) into a filtration system, utilising the negative pressure vacuum of an external fan. This type of (LEV) local exhaust ventilation is mostly used in industrial processes and fabrication workshops, as the extraction arms can be specifically positioned to point directly at the point of emission.

Local Exhaust Ventilation For Dust & Fumes

Is there a difference between a fume extraction arm and a dust extraction arm?

The specification of a local exhaust ventilation arm is more dependent on the specific activity it is being used for, as opposed to whether it is being used for the extraction of dust or fumes. For example, our food-grade extraction arms come equipped with either a stainless steel food-grade hood or an ATEX hood. This type of hood positional device is essential for the food industry when there is a risk of exposure to flours, grains, powders, and other airborne dust contaminates.

Dust and fume extraction arms for welding and fabrication processes tend to be articulated and have a greater range of motion, with integrated dampers allowing for greater control of airflow. You can read more about our welding fume and smoke extraction arms here

In some instances, businesses cannot install a static extraction arm, so a mobile extraction arm is a better option allowing for greater flexibility. Our Weld X Pro is a mobile dust & fume filter unit designed to offer a full 360-degree rotation of the arm and is designed specifically for the welding industry. It supports CoSHH and the HSG258 Guidance document on air recirculation and can be up and running in a matter of minutes.

Flextraction Dust & Fume Extraction Arms In Action

Fresh Air By Design - Our LEV extraction arms (hood positioning devices) are designed to enable the correct positioning of the hood to maximise the removal of dust and fumes generated around your working environment.

They are vital part of any LEV system, as they allow fumes and particles to be drawn away from the operator's breathing zone and into the main extraction duct. This prevents the operator from being exposed to harmful fumes and particles and ensures that they are able to work safely.

What Are The Benefits of Using An Extraction Arm?

10 Key Benefits of the Flextraction range of Flexible Extraction Arms:

- A self-supporting mechanism capable of carrying various hoods and hose combinations.Self-supporting mechanism capable of carrying multiple hoods and hose combinations.

- A twin support tube allows for the simple fixing of a solid duct or flexible hose in various diameters.

- Support clips allow the duct to be easily removed for cleaning and reinstallation.

- An increased surface area of all joints gives a much lighter feel to the extraction arm, allowing for easier positioning and support in any required position.

- Our LEV arms are fitted with a single or twin spring supporting mechanism to accommodate greater lengths and larger weights.

- The rear boom extension gives the extraction arm a 270-degree pivot, significantly improving the working radius.

- Integrated hood dampers allow greater control of the airflow in an extraction system.

- A 360-degree rotating swivel hood allows for more accurate positioning of the hood.

- ATEX compliant and stainless steel (food grade) versions are available.

- The installation of our flexible extraction arms is fully customisable. Choose between standard wall-mounted, ceiling-mounted or floor stanchion. We also supply a range of hoods including, flared hoods, fishtail hoods, ring hoods, and spun bell mouth hoods.

What Industries Could Benefit From Using An LEV Extraction Arm?

Safely remove dust & fume contaminates

The main benefit of using an extraction arm to remove dust and fumes from a working environment is the capability of source capture extraction. In many instances, an ambient air filtration system or a fume extraction canopy does not provide sufficient extraction. To provide a safe working environment, an LEV arm is the best option as it can be specifically positioned to point the hood at the point of harmful emission.

The most common industry that benefits from the specific use of an extraction arm is the welding industry. The vast majority of fabrication and metal construction processes utilise welding as a process. many companies opt for the use of an articulated or telescopic extraction arm as they allow for the capture of fumes at the point of source. In some instances, a business may opt to use a mobile welding dust and fume extraction unit instead of, or as part of their overall LEV system. The Weld X Pro is fully mobile, allowing the mobile filter unit to be easily positioned to suit the needs of the welder.

We offer comprehensive local exhaust ventilation (LEV) systems for a spectrum of working processes including vehicle fumes, welding dust and grinding. We can also provide solutions that are tailored to meet your specific needs in Vehicle Emissions Control Area's body shops or Laboratories where there is a potential exposure risk from harmful material emissions!

In addition to this, we also provide the food industry with a range of dust and powder extraction solutions. Alongside our Downflow Booths, our Food-Grade Extraction Arms help businesses provide a workspace free of hazardous contamination. From large-scale bakeries to food production lines, our team of engineers design, build and install Local Exhaust Ventilation systems to keep food manufacturing workspaces both clean and safe.

Hoods, Hoses and Brackets For Your Extraction Arm

The choice of the correct hood, in conjunction with the correct operational use of your extraction arm, is fundamental to its success as a dust and fume extractor Factors that must be considered are the product and process being extracted and the distance from the hood to the process. Get that right and you will vastly increase the effectiveness of the extraction arm.

Our local exhaust ventilation arms can accommodate a wide range of different hoods, including flared, curved fish tail, spun bell mouth and ringed.

- Polyester Coated (Black)

- Texture Conductive (ATEX)

- Stainless Steel

- Polypropylene

Click here for more information on our hoods & brackets

At Flextraction, we pride ourselves on being able to offer a comprehensive range of quality flexible extraction hoses suitable for many standard solutions and normally available from stock. They comply with a wide range of standards and specifications in the most diverse of industries, including the ATEX Directive, FDA conformity and food regulations.

For sales, advice and support, contact Flextraction's team today!

- 01664 410 641

- sales@flextraction.co.uk

Be first to hear of our special offers!